Introduction to Anti-Oxidants and Preservatives

View complete PDF version of this document HERE

Anti-Oxidants for Winemaking

Anti-oxidants, principally in the form of Sulfur Dioxide, are a critical chemical component of winemaking. They inhibit unwanted oxidation reactions (such as vinegarization) as well as assisting in sanitation, flavor, color, and structure stabilization in the wine, and longevity of the wine.

Sulfur Dioxide (SO2)

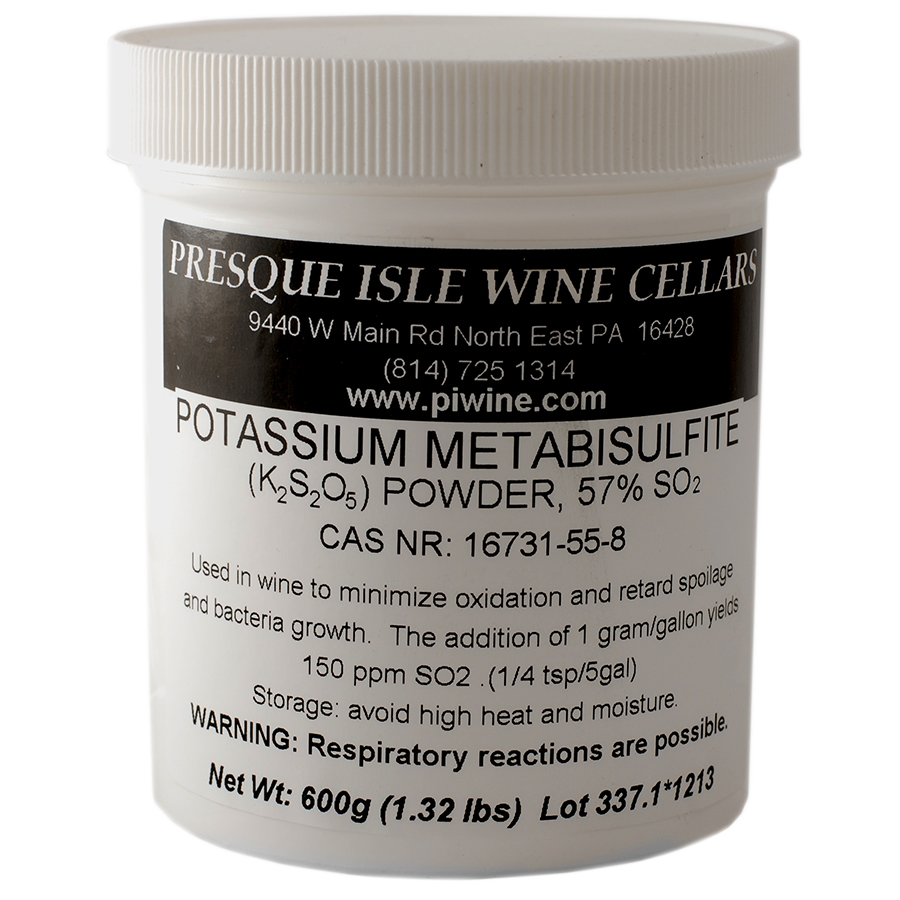

This most versatile of winemaking chemicals comes as close as anything to being recommended for all wines. It inhibits molds, bacteria (including the malo-lactic strains) and yeast cells, but with the latter it is selective; most of the more desirable strains for wine fermentation are more tolerant of sulfites than other strains. It is an effective antioxidant, for which there is currently no suitable substitute. Sulfur dioxide is a gas that is released into the wine or juice when potassium metabisulfite, campden tablets, or other sulfite compound is added. It is also the irritating gas produced when you burn a sulfur wick or pastille. It will not act as a magical additive to prevent a wine from spoiling, nor will it restore one which has been abused, but it will, when properly used, aid in preserving an otherwise sound wine.

(including the malo-lactic strains) and yeast cells, but with the latter it is selective; most of the more desirable strains for wine fermentation are more tolerant of sulfites than other strains. It is an effective antioxidant, for which there is currently no suitable substitute. Sulfur dioxide is a gas that is released into the wine or juice when potassium metabisulfite, campden tablets, or other sulfite compound is added. It is also the irritating gas produced when you burn a sulfur wick or pastille. It will not act as a magical additive to prevent a wine from spoiling, nor will it restore one which has been abused, but it will, when properly used, aid in preserving an otherwise sound wine.

Some people show allergic reactions to sulfur dioxide (SO2), almost always as asthmatic reactions to high levels of atmospheric SO2 rather than in aqueous solution as it occurs in wine. It has been used since the Middle Ages in most wines. It is produced in normal fermentations and may occur even when no sulfur additives have been used. Each of us produces SO2 in our normal metabolism as well. There have been numerous attempts to demonize SO2 for reasons a cynic might describe as other than science.

A few people are truly allergic to SO2. About one in every four hundred people will have an overt reaction. For most it is a mild skin flush or headache. There are many other unavoidable contacts with SO2 than one is likely to get from wine.

Use of Sulfur Dioxide

Sulfur Dioxide is often used before fermentation by adding 50 to 80 parts per million (ppm) [= mg per liter] of sulfites a few hours before adding a yeast culture. Wild yeast strains are less tolerant of sulfur dioxide than the better wine strains which recover more quickly and then dominate the fermentation. This is common practice with whites but less so with reds where a quick startup is highly desirable. Some wineries use no sulfites prior to fermentation. Unless there is a high concentration of spoilage organisms (typically from bird pecked fruit or machine picked fruit left around too long before processing, or from diseased fruit), it is likely that the final quality of the wine won’t suffer.

- If you choose not to use a commercial strain of wine yeast culture and trust to fermentation by wild yeasts, the better strains will recover more quickly and dominate the fermentation. Typical prefermentation use of SO2 is about 30 to 60 ppm when using this practice.

- The addition of SO2 at each racking after fermentation has ended and at bottling will do much to retain the fresh flavors in wine, especially with whites. Adding 25 to 50 ppm at each transfer would be typical. Use less at lower pH levels and more with high pH wines or when there is residual sugar. Red wines generally need less SO2 than whites because of the anti-oxidative properties of tannins.

- When using a sulfite solution after cleaning to supress bacteria, add about 1/2 teaspoon per gallon of water (=450 to 500 ppm SO2) and an equivalent weight of citric acid (other acids can be used for this purpose) to reduce the pH of the water below pH 3.5 which will greatly increase the anti-microbial effectiveness of the sulfur dioxide.

- It is very poor practice to add SO2 to wines which are still fermenting. The SO2 quickly becomes tied up in a bound form which won’t help in inhibiting microbial growth or oxidation; production of acetaldehyde proceeds and may adversely affect wine flavor.

Refer to our article on Use and Measurement of Sulfur Dioxide in Wine for additional information on sulfur dioxide in winemaking.

Preservatives

Preservatives, typically potassium sorbate, are used in winemaking to inhibit latent yeast and prevent secondary fermentation especially in sweet wines. Sulfur Dioxide also has some preservative effectiveness which is conveyed as an additional benefit from it primary use as an antioxidant.

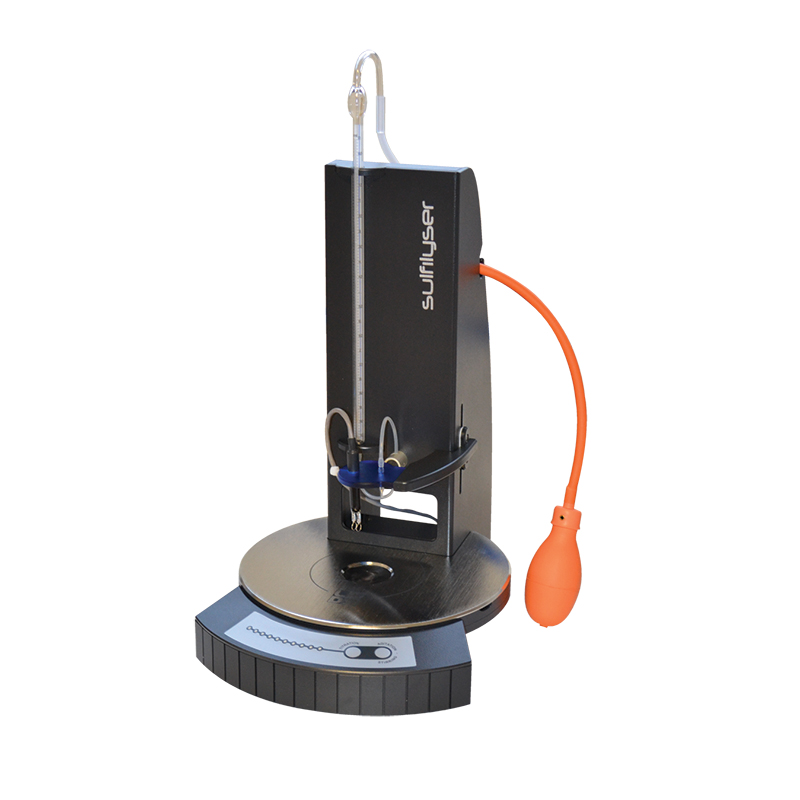

Potassium Sorbate is a yeast inhibitor used to prevent further fermentation in wines with residual sugar. It doesn't kill yeast, but prevents them from dividing to produce new yeast cells. It also does not inhibit the growth of malo-lactic bacteria and malo-lactic fermentation occurring after the addition of sorbates will produce an undesirable distinct off-odor of geranium leaves. This problem can be forestalled if you maintain at least 50 ppm of free sulfur dioxide after sorbates are added to the wine. Refer to the Free SO2 Testing category for more information on testing for free SO2 levels.

Potassium Sorbate is a yeast inhibitor used to prevent further fermentation in wines with residual sugar. It doesn't kill yeast, but prevents them from dividing to produce new yeast cells. It also does not inhibit the growth of malo-lactic bacteria and malo-lactic fermentation occurring after the addition of sorbates will produce an undesirable distinct off-odor of geranium leaves. This problem can be forestalled if you maintain at least 50 ppm of free sulfur dioxide after sorbates are added to the wine. Refer to the Free SO2 Testing category for more information on testing for free SO2 levels.

Best practice is to add the sorbate to the mixture of sugar and water used to sweeten the wine, because the sorbate dissolves better in a warm liquid. There is never any reason to add potassium sorbate to a dry wine.

Potassium sorbate should be stored where it is dry and out of direct sunlight. Even with proper care shelf life is normally only six to eight months. Normal usage is 1 to 1-1/4 grams per gallon of wine (=1/2 to 3/8 teaspoon per gallon). This is the equivalent of 200 to 250 ppm.

RETURN TO WINEMAKING 101 SHOP ALL CHEMICALS AND ADDITIVES